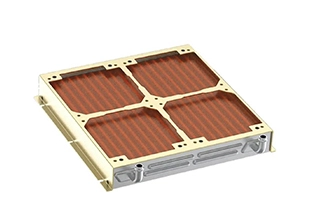

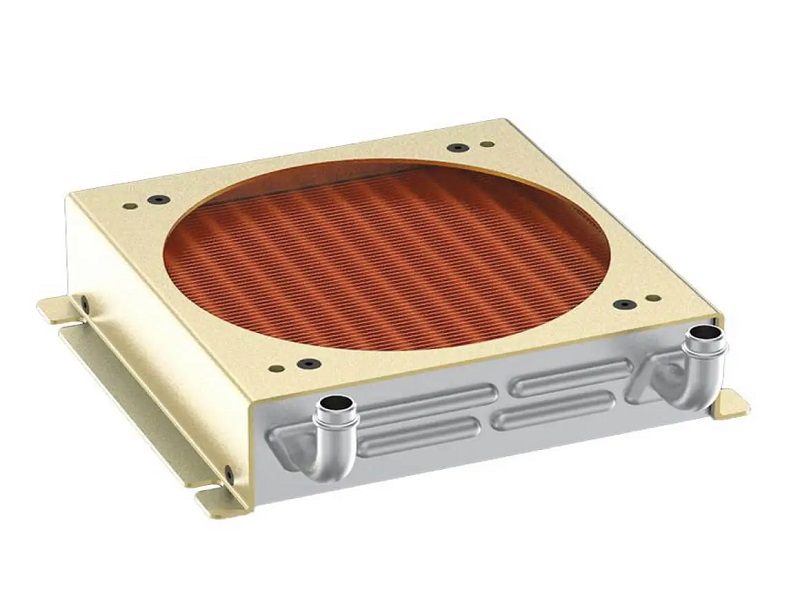

With the continuous development of modern industrial technology, stainless steel materials have been widely used in multiple fields due to their excellent corrosion resistance and mechanical strength. Among them, stainless heat exchangers have become indispensable equipment in industries such as energy, chemicals, food, and pharmaceuticals due to their excellent performance and wide applicability.

Stainless heat exchangers are mainly manufactured using high-quality stainless steel materials, boasting outstanding corrosion resistance, especially suitable for environments with high temperatures, high pressures, and corrosive media. The stainless heat exchangers launched by CI Industry adopt advanced channel design, allowing the hot and cold fluids to fully mix internally, significantly enhancing heat exchange efficiency, reducing energy consumption, and extending the equipment's service life.

Material Type: Austenitic Stainless Steel

Currently, austenitic stainless steel is the mainstream material used in manufacturing stainless heat exchangers. It contains a high proportion of chromium (≥17%) and nickel (8%-15%), and elements such as molybdenum, titanium, and niobium can be added according to specific needs. This material has excellent corrosion resistance, superior welding performance, and good plasticity, making it very suitable for high-strength, long-period working heat exchange equipment.

Solution Treatment

To enhance the corrosion resistance of austenitic stainless steel, the solution treatment process is usually adopted when manufacturing stainless heat exchangers. This process involves heating the steel to 1050-1150℃ and then rapidly quenching it with water, aiming to dissolve the carbides into the austenite and retain them at room temperature, thereby significantly improving corrosion resistance and effectively preventing intergranular corrosion.

Stabilization Treatment

For stainless steels containing Ti or Nb elements, an 850-880℃ stabilization treatment is performed after solution treatment to allow carbon to preferentially combine with titanium or niobium, preventing the formation of chromium carbides. This process is particularly important for stainless heat exchangers, as it effectively extends the equipment's corrosion resistance life and ensures long-term stable operation.

Stress Relief Treatment

To reduce the residual stress from cold working or welding, some stainless heat exchanger components need to undergo stress relief treatment at 300-950℃. This process can mitigate the tendency for intergranular corrosion and improve overall stress corrosion resistance, especially suitable for thin-wall structures and high-pressure conditions.

CI Industry’s stainless heat exchangers optimize structural design, achieving fast heat exchange while reducing fluid resistance and energy loss. Their advantages in the mixing efficiency of hot and cold fluids make them exemplary products for high efficiency and energy saving. Whether in industrial boiler systems, petrochemical equipment, or food production lines, stainless heat exchangers can ensure production continuity and energy utilization efficiency with their stable performance.

As the demand for corrosion-resistant, high-strength, long-life equipment in industries continues to grow, the importance of stainless heat exchangers is becoming more significant. From material selection and heat treatment processes to channel structure optimization, each link is directly related to the product's reliability and service life. Serving as a bridge between manufacturers and industrial users, high-performance stainless heat exchangers play an increasingly critical role across various industries with their comprehensive advantages.